Manufacture of high power ultrasound equipment using Rubiitpower Technology has been focussed on the design of large flow - continuous treatment chambers (flow cells) causing the cost per volume material treated to be reduced Improved energy efficiency of the equipment. The efficiency of Rubiitpower ultrasonic generators and Processor transducers has been improved over the years, thereby reducing internal heating and provision of specially designed in-expensive cooling systems), Easy to install and/or retrofit systems with improved efficiencies, the size of generator, cooling system and other parts are easily installed into an existing facility at Competitive energy costs. Depending on the application, the amount of energy required per liter material treated (often defined as kWh/L) is comparable to any other type technology unit operation in the industry (for example homogenization, milling, heat shock, etc.) Low maintenance cost is One of the main benefits of Rubiit technology in the absence of moving parts,the lack of rotors, seals, grease, etc. makes these systems particularly robust.

Rubiit Technology is Strong potential for intellectual property. While high power ultrasonic Processor systems become more and more standardized, the way the energy is applied to the medium (for example, flow cell design, number of transducers, piping arrangement, etc.) is unique for every application. Therefore, the potential to obtain patent protection is relatively large.

Application |

Description |

Benefit (laks/yr) |

Investment2 (k$) |

Payback time |

Defoaming |

Increased production capacity |

600 |

60 |

6 weeks |

Emulsification |

Reformulation & improved shelf-life |

300 |

300 |

1 year |

Extrusion |

Increased production capacity |

350 |

75 |

3 months |

Extraction |

Yield increase |

1200 |

400 |

4 months |

Waste treatment |

Enhanced digestion & renewable energy |

300 |

75 |

3 months |

As a result of the reasons mentioned above, the technology provides a strong economic business case in a range of food processing applications, which to date are only known by those involved in the application development due to confidentiality restrictions. An outline of several business cases based on realized projects is provided in Table.

Rubiit High Power Online Ultrasonic processors in the food industry

Application |

Mechanism |

Benefit |

Extraction |

Increased mass transfer of solvent, release of plant cell material (cavitational dislodgement) |

Increased extraction efficiency, yield in solvent, aqueous or supercritical systems |

Emulsification/ |

High shear micro-streaming |

Cost effective emulsion formation |

Crystallization |

Nucleation and modification of crystal formation |

Formation of smaller crystal formation during freezing |

Filtration/screening |

Disturbance of the boundary layer |

Increased flux rates, reduced fouling |

Separation |

Agglomeration of components at pressure nodal points |

Adjunct for use in non-chemical separation procedures |

Viscosity Alteration |

Reversible and non-reversible structural modification via vibrational & high-shear micro-streaming. Sono-chemical modification involving cross-linking and restructuring |

Non-chemical modification for improved processing traits, reduced additives, differentiated functionality. |

Defoaming |

Airborne pressure waves causing bubble collapse |

Increased production throughput, reduction or elimination of antifoam chemicals and reduced wastage in bottling lines. |

Extrusion |

Mechanical vibration, reduced friction |

Increased throughput |

Enzyme & microbial inactivation1 |

Increased heat transfer and high shear. Direct cavitational damage to microbial cell membranes |

Enzyme inactivation adjunct at lower temperatures for improved quality attributes |

Fermentation1 |

Improved substrate transfer & stimulation of living tissue, enzyme processes |

Increasing production of metabolites, acceleration of fermentation processes |

Heat Transfer1 |

Improved heat transfer through acoustic streaming and cavitation |

Acceleration of heat Availability of high amplitude/power units for large commercial operations |

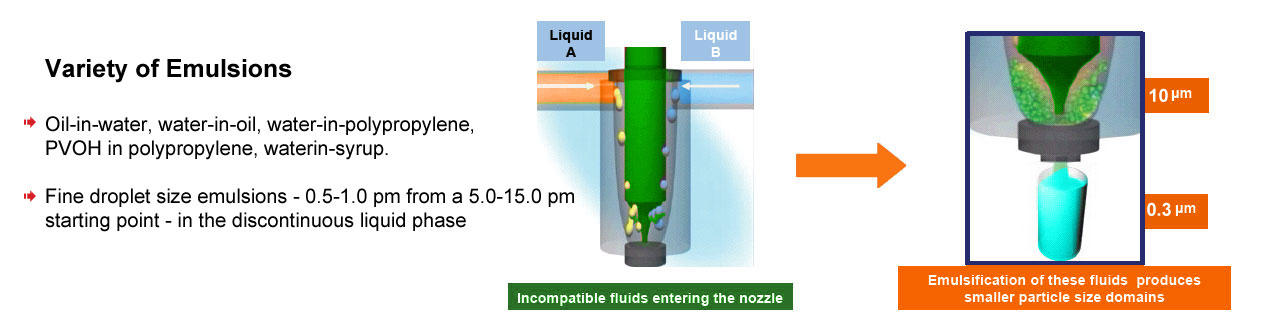

Spray Atomization for Mixing/Emulsification

Ultrasonic Liquid Processing Technology

Mixing: |

Emulsifying: |

Dispersing/Degassing: |

• Continuous processing of multi-component ink formulations possible • Able to effectively handle components of different viscosities (1-1000 cps) • Enables sequential addition of sensitive or reactive components • Achieves processing without introducing unwanted entrained air |

• Produces highly stable emulsions with reduced or no additives • Able to emulsify difficult components • Smaller droplet size emulsions possible • Achieves processing without generating foam, even with surfactants present |

• Provides effective breakup of pigment agglomerates • Extracts dissolved gasses from liquids • Capable of dispersing nanoparticles |

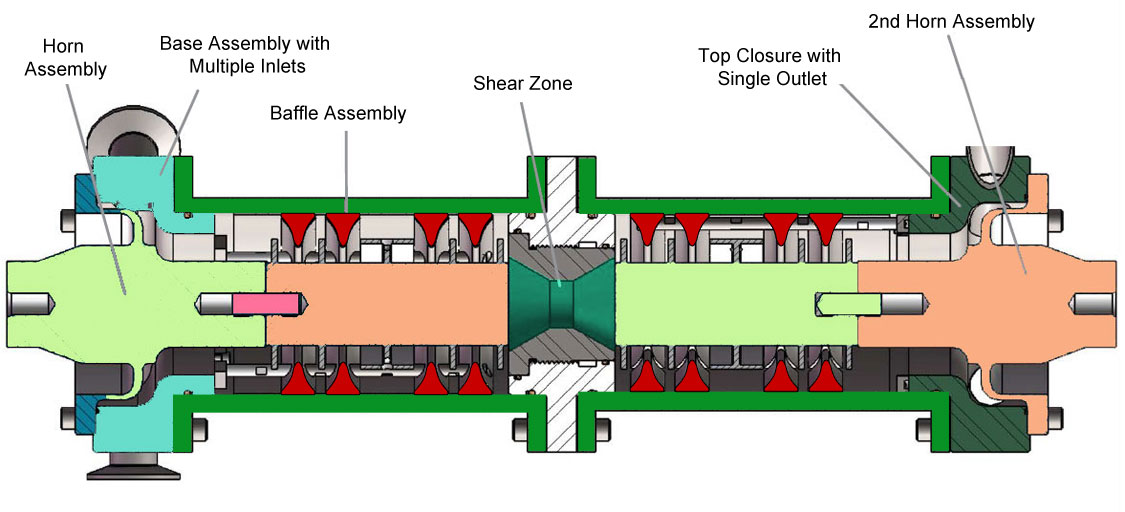

SINGLE HORN SYSTEM/DUAL HORN SYSTEM

Oil

Ultrasonic processor transducers (Oil Exploration)

-

-

Wax depositions in drilled oil wells are complex mixture of heavy solid alkenes, asphateues, sand grain, precipitated salts, rust and entrapped water and depend on wax content viscosity and flow rate loss of gas and temperature lowering below cloud point temperature (CPT) results in precipitation of wax and asphalteues increasing oil viscocity forming organic depositions choking off flow lines. Wax deposition and gelation renders pipe lines and pumping equipment unusable, reducing oil production rate and closure of wells. Ultrasonic processor transducers of 1000 – 5000 Watts are used