Microprocessor Controlled Cleaner

-

-

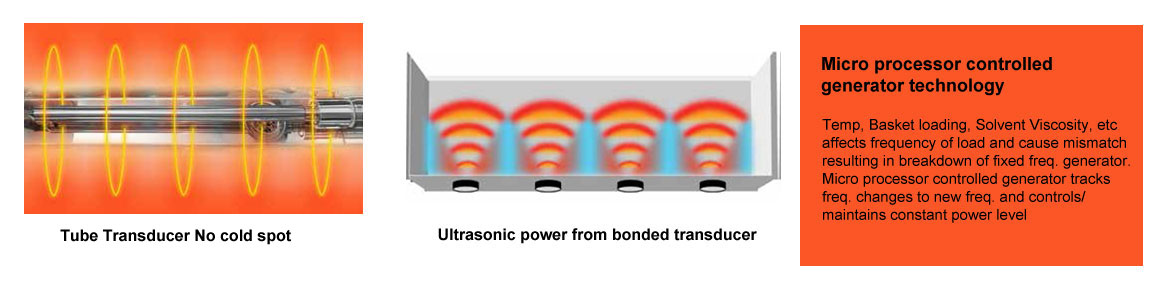

Microprocessor controlled ultrasonic generator tracking frequency & power for highest reproducibility and micro-processor controlled/Set process (Time, optimum power, temp.) for repetitive confirmatory process / production.

Immersible Transducer RIT

-

-

Sealed immersible S. S. Bricks Provide Versatile way to add Ultrasonic’s to new/ existing tanks Custom-built in four mounting options for placement

RTT Tube Transducer

-

-

• Immersible Tube Transducer

• Microprocessor controlled generator.

• Radial (360°) power transmission.

• Length - 300mm to 2000mm

• Diameter - 40mm to 70mm.

• Power - 300 Watt to 2000 Watt.

• Easily replaceable. Can be positioned at any angle.

• Can be installed in existing large pre-plating pre-anodizing / pre-phosphating tank to convert it to ultrasonic tank or wash pharmaceutical vats/ reactors.

Aqueous M Modules designed for

-

-

• Heated immersion & Turbulation with dunking/ Rotation.

• Hot Spray & Dunking/Rotation

• Ultrasonic Immersion & Dunking/Rotation.

• Hot Air knife drying with dunking.

• Each module has tank, pneumatic lifting & dunking, optional heaters, Ultrasonic, Spray Pump & flooding facility, pneumatically powered lid basket transfer platform with rollers. Linear transfer system with linear slide and multiple basket shifting arms/gripper does horizontal Basket Transfer.

Custom-built cleaning systems for large cleaning volumes and highest degree of cleanliness. Solvent or Aqueous based cleaning systems are manufactured, designed for single or multi-stage installation with filtration, recirculation, heating, drying and material handling system with PLC & optional Enclosure

AQUEOUS BASED Multi-function Multi-process Technology

Vac-u-Ral Aqueous Automatic with Vacuum

-

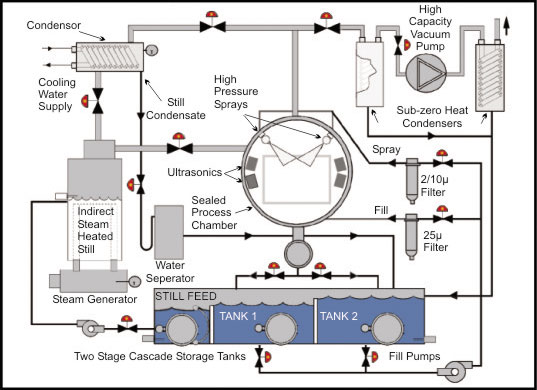

For precision cleaning of complicated shaped articles/blind holes/galleries.

• Vacuum ultrasonic system powerfully cleans complicated shapes, blind holes

• Vacuum drying system drastically reduces boiling Temp, drying time, cost.

• Distilling / recycling device always provides clean liquid for rinsing.

Solvent Based Multi-function Multi-process Technology

How Vacuum works?

-

Reduced pressure Causes Air bubbles in holes to expand, flushing out contamination. Complete filling of cavities takes place only when system generates Vacuum. Ultrasonic waves under vacuum and then at atmospheric pressure loosens all contamination. Reduced Pressure causes solvents or water to boil at lower temperature and dries the component faster. Rotating basket helps complete cleaning and drying of all galleries.

Ultrasonic Hospital Cleaning

-

Hospital Surgical Instrument - Designed to keep up with the hectic schedule of today’s Central Sterile Departments, CSD Clean Systems can process two complete sets of baskets in 13 minutes.

This complete system is userfriendly with automatic lifts with slide & lock baskets.

• Ultraviolet Water Deactivator • Automatic Load Tray Elevator • Slide and Lock Baskets: Simple and efficient tray loading • 36 dedicated ports for cannulated instruments with 3 baskets • 20 Robotic instruments per cycle • 40 pounds total weight capacity • Dual purpose: Can be used with hospital baskets • Easy-to-use 7 inch touch-screen with programmable timer • Fully automatic degas, wash, rinse and air purge completely eliminates waiting time for degassing • Tap, RO or DI water compatible • 220-Volt wall receptacle • 600 MM W x 1250 MM D x 2000 MM H (lid open) • 13 Minute wash cycle • Industry exclusive TT (ultrasonic Tube Transducer)

Every basket can process up to 10 robotic orcannulated instruments. With our custom adaptors, and Robotic Arm Cleaning Systems baskets (RACS),

Ultrasonic & Multi-Process Cleaning & Vacuum Drying & Material Handling In Aerospace, Auto, Engineering, Nuclear, Defense, Metal Industries & Hospitals