Welcome to the world of Possibilities -

Make In India & Explosive Growth in

Manufacturing in India

Buy Now 35 Technologies FOR 101 Products

With Designs, Drawing, Application / Marketing Knowhow & Marketing Backup

Buy Now 35 Technologies FOR 101 Products

With Designs, Drawing, Application / Marketing Knowhow & Marketing Backup

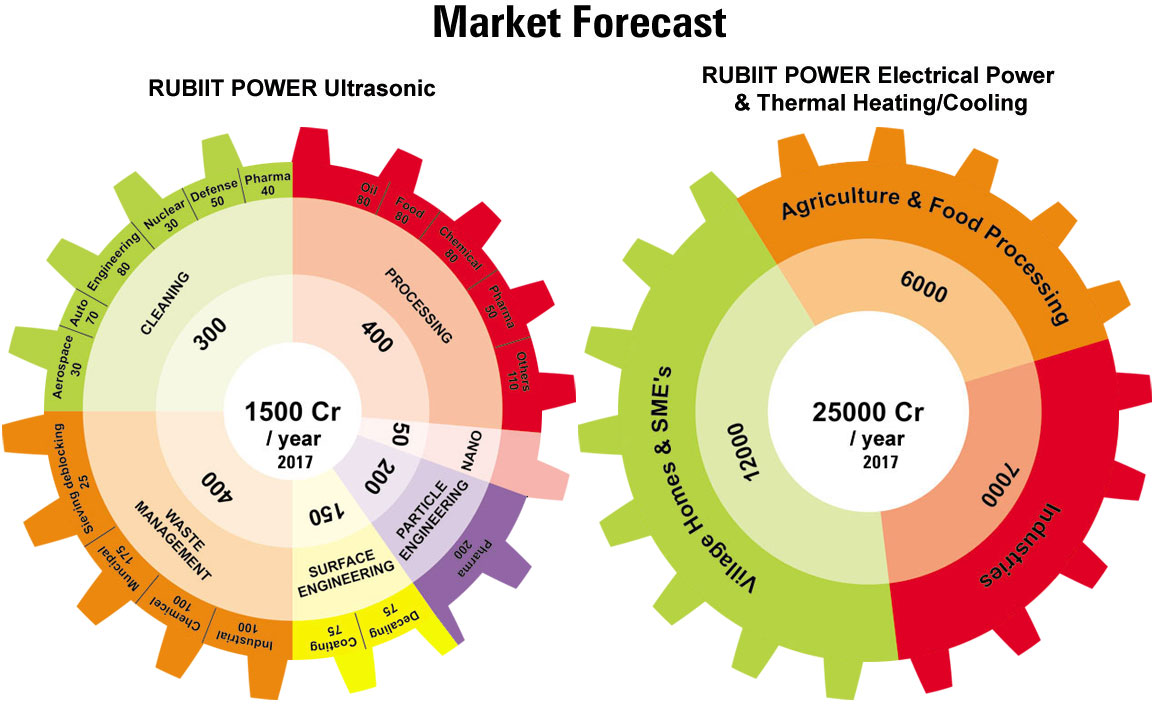

Establish Premium Share Of 1500 Crore Market

TECHNOLOGIES FOR MANUFACTURING EQUIPMENT REQUIRED IN FOLLOWING INDUSTRIES

1) Auto-Mobile 2) Engineering 3) Metal- Wire, Rebar Descaling & Sheet Galvanizing 4) Nuclear Power 5) Aero-Space 6) Chemical 7) Pharmaceutical 8) Oil/Gas Production 9) Electrical Power Production 10) Defense

The Rubiit Power ultrasonic technologies market provides alteration/Improvement of processes with the use of oscillating sound of very high frequency. It is expected that the market would grow at Highly respectable rate of 20 % as the technology will have to be widely adopted in Manufacturing, Quality & Output improvement to meet MAKE IN INDIA and CLEAN-GREEN India Challange.

Various verticals such as industrial units and healthcare are using ultrasound as it is considered a highly efficient technology. In the industrial sector, these can be used for Cleaning, Coating, Mixing and processing liquids/solids ,Waste-management and forMicronization as well as Re-engineering of molecules in Pharmaceutical Industries.

All Rubiitpower Technologies bring together Envoirnmentally clean Technologies with Elegant Designs , Intelligent Integration & state of the Art Performance. But there is a Lot to Tell & Many More Applications. Expected Product Market is well over Rs 1500 Cr for equipment and 25000 Cr for POWER PREODUCTION by 2017 as detailed below.

About Rubiitpower Mumbai India

Suhas Ralkar,

Mobile - +91 9322 699 129, +91 9322 292 666

Education- Post-graduate Electronics

Research Experience Abroad – Research Experience Abroad – Three years - two years in Power Ultrasonics , One year in development of First Multi-element transducers and Pulsars for Sono-graphy eqpt. Returned to India & set up Ralsonics in1973

Over the Last Fortytwo Years Ralsonics has developed 38 RUBIIT (Ultrasonic) technologies and Manufactured Ultrasonic Eqpt for about 101 applications.

Ralsonics Landmarks

1973 - 80 - Ralsonics manufactured 1100 fetal heart monitors & Systems 1500 Ultrasonic cleaning Eqpt of 120 watt to 5000 watt capacity 300 ultrasonic thickness guage eqpt.1980 - 2010 - Manufactured 5200 ultrasonic cleaning Eqpt including about 500 Automated Multistage ultrasonic cleaning plants and supplied to BARC, NPCIL, HAL,DEFENCE ISRO, RAILWAYS, AIR HQ, Leading AUTO & Engineering Industries. This included complete supply to RMP Mysore first phase and 80% requirement of Nuclear Fuel Complex and 90% eqpt procured by HAL Koraput Engine manufacturing unit over the Period.

2001 - Development of TT Tube transducer. (Only Indigenous effort to date and one of four in the world) Powered by Micro-processor controlled- MPG- frequency tracking Mosfet/IGBT based generator of 1000 watt capacity.Extensive use in Automated plants as easily replaceable and can be located for placement at any angle in customers installation

2002 - Design of special eqpt for Uranium dust recovery from Hepa filters for Nuclear Fuel Complex

2003 - Development of RUSSEL- Ralsonics UltraSonic Spray ELectronic Process for Online Pre-Galvanising cleaning at 300 meters/minute speed for 100% removal of Oil, Carbon ,dust and Iron fines and drying before Galvalum coating of CR sheet for Auto and White goods application 2004-Largest single 92 kw RTT with MPR Generator installation manufactured for single customer

2004 - Largest single 92 kw RTT with µP Generator installation manufactured for single customer

2004 - 2005 - Ultrasonically Cleaned rinsed& dried 14640 holes of 450 mm length and 13mm diameter in stub of four steam generators using specially designed 10 mm diameter Tube transducer for NPCIL at Larsen &TubroPowai premises, Boroscopically examined and certified the acceptability of good holes as per their standards

2005 - 06 - Development of Internal Cleaning of Pipes by External Ultrasonic Transducers for Chemical ,Pharmaceutical, Food & Nuclear Industry. Tested On Mock-up at NAPP Narora

2006 - 07 - Four Nuclear DECONTAMINATION Centres supplied to NPCIL at Kaiga, TAPP, RAPP through EPC

2008 - 2010 - Development of RUBIIT – Resonant Ultrasonic Bubble IonisationImplantation Transmutation -The Proprietorytechnology for Online Cleaning, Scale-removing ,Coating & Nano-scale Surface structuring of Metal wires of diameter 0.44mm to 4mm, metal rods of 4mm to 20 mm & TMT construction Rebar of 6mm to 32 mm .The Major Indian Steel Manufacturer had approved the Technology for their long steel products and released project for Joint construction of eqpt., Coating of Zinc , Nickel, Titanium, Molybdenum on steel wire has been tested inhouse.

2011 - Design and manufacturing and supply of Single chamber Multi-process EFVD Emission Free Vapour Degreaser for TCE /other air polluting carbon based solvents with Combined Ultrasonic, Vacuum, Vapour cleaning and Vacuum drying costing Rs two crores for the Indian Aerospace Manufacturer and another Foreign collaborated Aerospace Component Manufacturer

2011 - 2013 - Extension of RUBIIT technology for Electric Power production @ 40 paise per KWH unitusing Titanium, multi element was developed and succeeded in 3.5 kw generation. Further work on developing,Testing& modifying the technology for Distributed energy sources of 5 kwh / 101 20 Kwh is planned. Theory for understanding and backing the RUBIIT Tech is outlined.

2012 - 13 - Development & Production Of Ultrasonic Plasma Processor (UPP) Technology For Processing And Industrial/Chemical/Manure Waste-Management. Recovery of Metals is achieved.

2013 - Design & manufacture of multistage, degreasing, pickling,rinsing ultrasonic cleaning drying plant for one lakh brass bullet covers/shift based on rotating drum conveyor costing Rs. 4 crores was designed & manufactured. This is typically used for cleaning small electrical stamping hardware & mechanical hardware in pre-plating, coating operations. Elevan such units were commissioned at a Defense production unit.